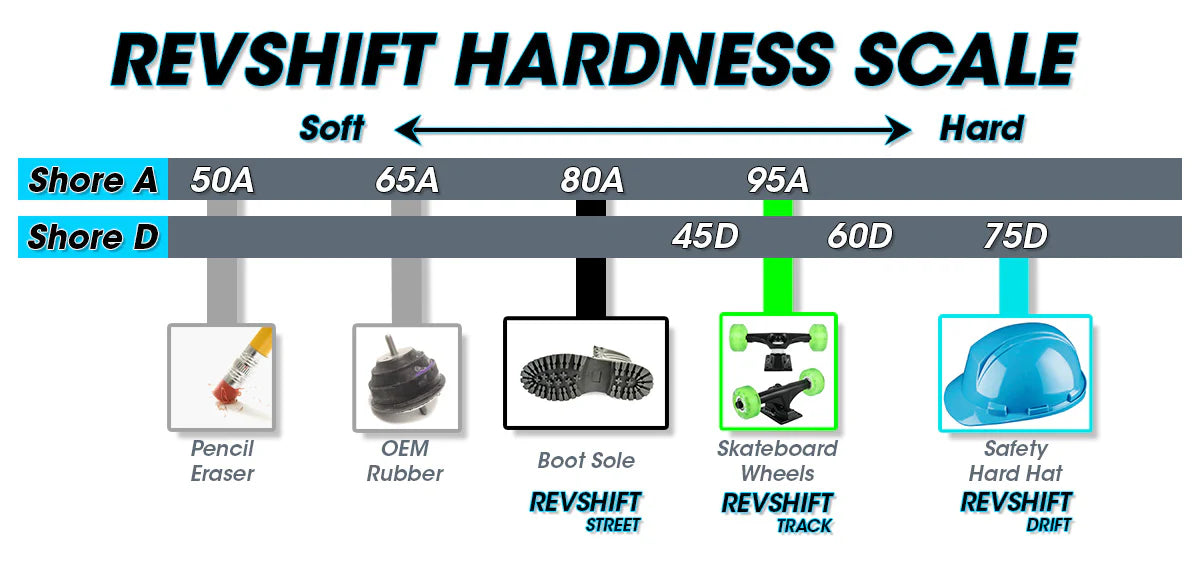

The goal of stiffening up the motor and transmission mounts is to reduce the movement of the drivetrain. This results in better handling and more power being directed toward the wheels. Motor and trans mounts are the most responsible parts for transmitting NVH (noise, vibration, harmonics) into the vehicle’s cabin. In other words, the harder you make the motor and trans mounts, the more vibration you will feel.

Suspension bushings are much more forgiving in regard to NVH. Most of the road noise and bumps are dealt with by your springs and shocks. Stationary mounting bushings such as subframe and differential bushings can be very stiff without noticing much of a difference in ride harshness. Rotational bushings such as control arm and trailing arm bushings are a little more noticeable the stiffer you go but still do not significantly impact ride comfort for the performance minded driver.

For a high performance street car, we generally recommend our 80A Street motor and trans mounts and our 95A Track suspension bushings. This combination will minimize NVH and reduce drivetrain movement as well as significantly improve the vehicle’s handling by stiffening up the suspension bushings.

Pro tip: In general, if you want to reduce vibration being transferred through the motor mounts at idle, raise your vehicle's idle RPM to 800-900 RPM. This speeds up the frequency of the vibrations and smooths things out a bit.